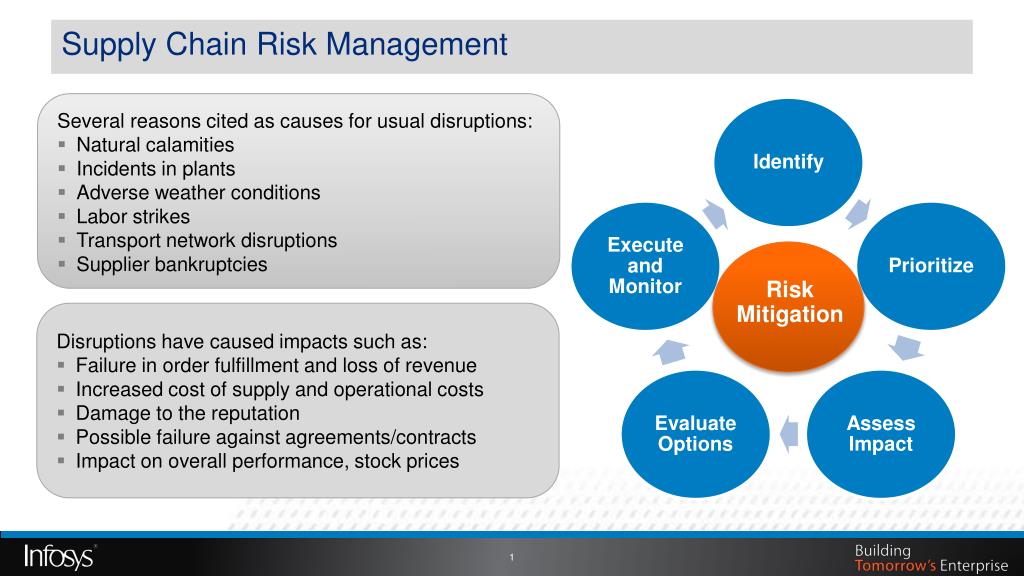

This blog post will discuss the key components of a successful risk management plan and how you can put one in place for your business. Therefore, it is important to implement a supply chain risk management solution to protect your business from these risks. For example, a sudden shortage of materials or a delay in shipping can cause production delays and lost sales. Read here about how Supply Chain Analytics can help intelligent manufacturing decisions along with manufacturing operational efficiency.Disruptions to your supply chain can have a devastating effect on your business. The complexity of today’s manufacturing environment has made the use of supply chain data analytics critical for identifying operational bottlenecks in manufacturing, eliminating supply chain waste, reducing possible fraud, billing anomalies, and risk patterns. Many organizations are now relying on advanced data analytics to look at not just the financial transaction information, but also some more specific operational details to really figure out where their potential risks lie. In order to truly understand the innate nature of supply chain risks, manufacturers need a supply chain optimization software to stringent processes and capabilities for supply chain data analytics. Using Artificial Intelligence to Mitigate Supply Chain Risks: Manufacturers would need to take ownership of both the supply and delivery processes to understand the inherent risk, regardless of who has economic responsibility for delivery according to the terms of the sales contract. They can globally source where savings are balanced by assurance of supply. Instead of abdicating to the suppliers’ delivery, manufacturers can plan logistics with task forces to bring items closer to the factory location and where it makes economic sense. Logistics is another key component that affects supply chain risks to a large extent. Here are 5 ways you can effectively mitigate risks and protect your supply chain in the long term: FAMILIARIZE WITH YOUR POTENTIAL SUPPLIERS Studies show that those manufacturers who proactively manage supply chain risks end up spending almost 50% fewer resources to manage supplier disruptions than those who stated that they aren’t proactive. With proactive supply chain risk management, other than identifying, assessing and mitigating risks, supply chain managers can avoid them and also save potential costs in the process. Five Strategies to Proactively Manage Supply Chain Risks These can help provide the basis for addressing risk by using appropriate measures to secure supply and protect the brand. RISK MITIGATIONįinally, manufacturers need to define both preventive action plans and reactive action plans for this risk. It is important to be aware of those partners who have a significant impact on sales, margins or profit. Next is to clearly define what possible impact a risk event could have on the manufacturing business. Manufacturers would first need to establish a risk profile and then enact active monitoring to keep it up to date.

The first step toward risk mitigation is to accurately identify it in the first place. The Supply Chain Risk Management Lifecycle involves three main stages to achieve supply chain resilience: RISK IDENTIFICATION The Supply Chain Risk Management Lifecycle From global losses due to earthquakes, floods, fires that reached $150 billion in 2019 to the nearly $350 billion in losses recorded in 2017, these high costs, in combination with long recovery times, have triggered many companies to reassess their supply-chain strategies to become more risk aware and to make them more resilient to any kind of disruption. As this happens, more and more global companies have begun questioning how to assess and manage these risks and therefore prepare their supply chains accordingly. Today’s complex supply chains are almost inevitably subject to disruption.

Supply Chain Risk Management (SCRM) is defined as the process of taking those strategic steps which can help manufacturers identify, analyze, assess, and finally mitigate the risk from supply chain disruption. A recent study by Deloitte revealed that almost 85% of surveyed global supply chains had experienced at least one disruption in the past 12 months.

0 kommentar(er)

0 kommentar(er)